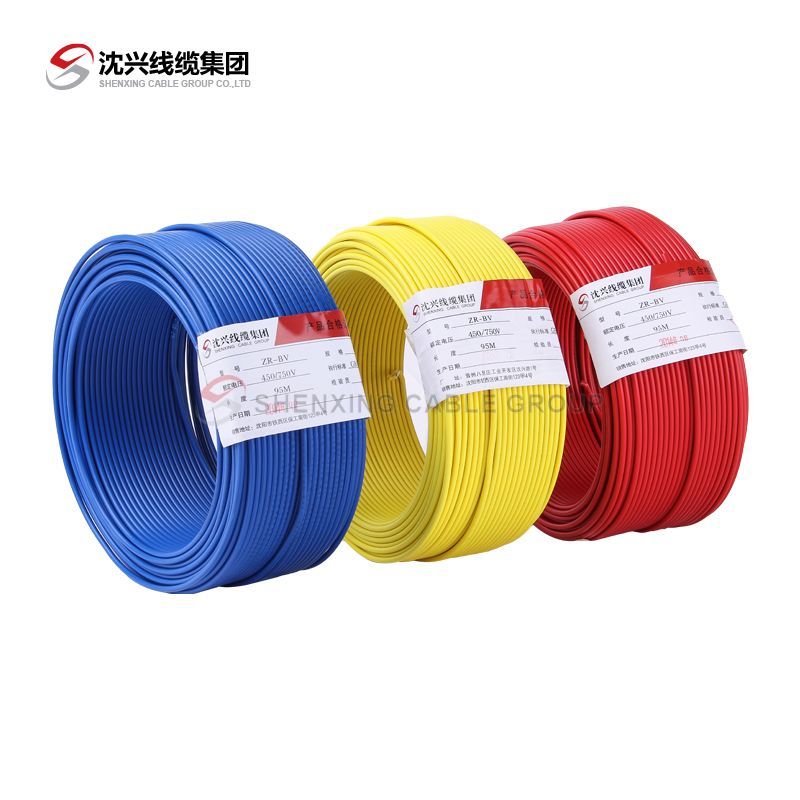

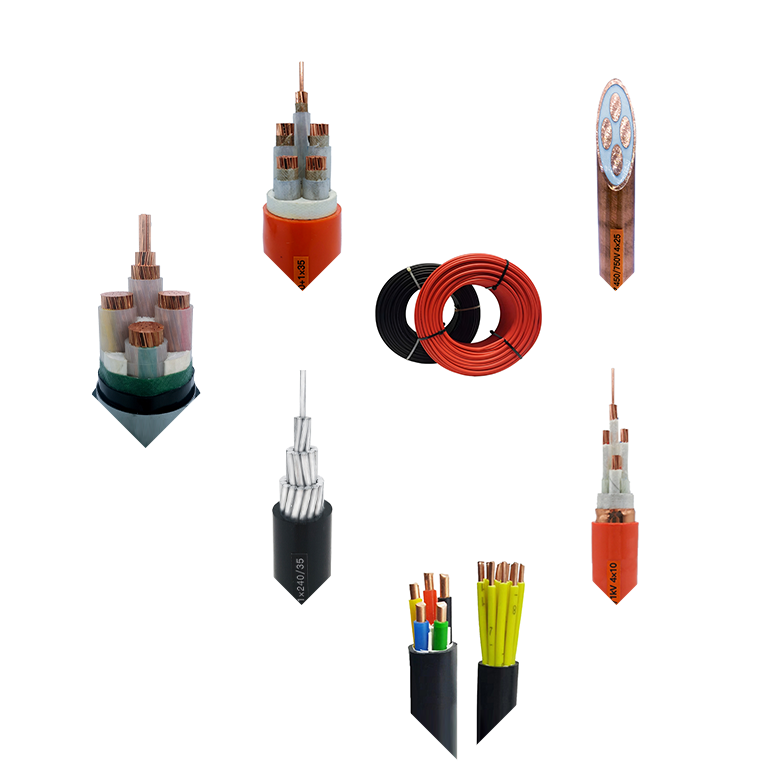

A large-scale wire and cable enterprise group integrating manufacturing, sales, design and research and development.

INQUIRY NOW

A large cale wire and cable enterprise group integrating manufacturing,sales, design and research and development.

INQUIRY NOW