+86 151 2718 0862

+86 151 2718 0862

A large-scale wire and cable enterprise group integrating manufacturing, sales, design and research and development.

INQUIRY NOW

A large cale wire and cable enterprise group integrating manufacturing,sales, design and research and development.

INQUIRY NOWEnsuring the Highest Quality Cable& Service

As a responsible wire and cable manufacturer, with the continuous innovation of industry needs, Shen Xing invested 278 million yuan to build a new high-temperature resistant, medium and high voltage special cable production workshop and a multifunctional three-story test building integrating R&D, testing and display to ensure that each product meets industry standards and meets customer needs.

Whatch VR

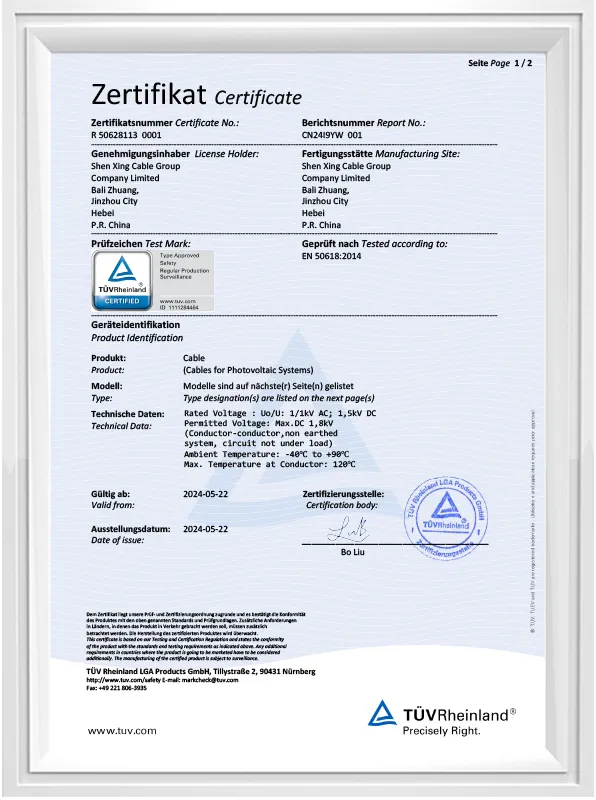

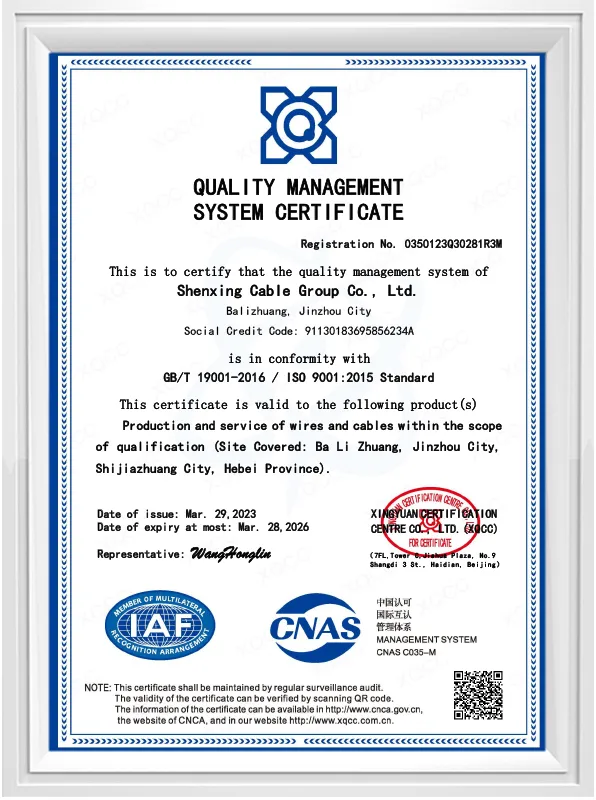

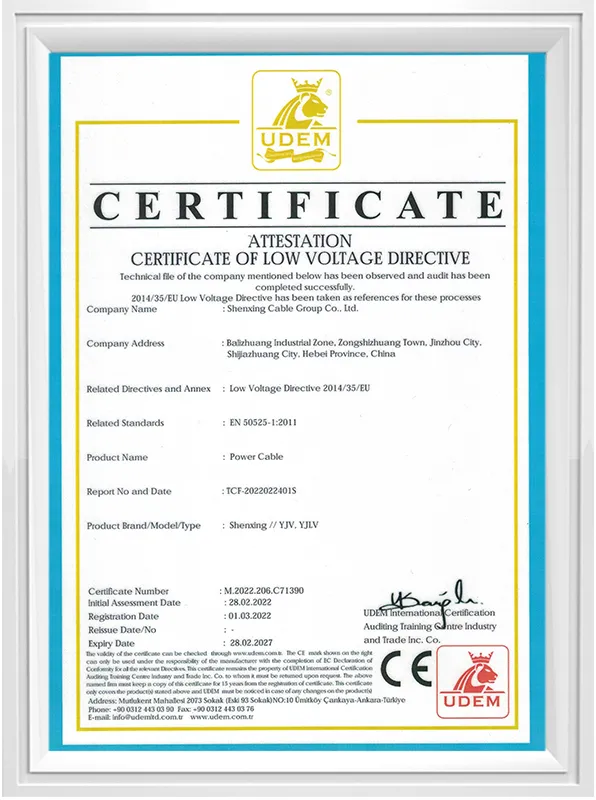

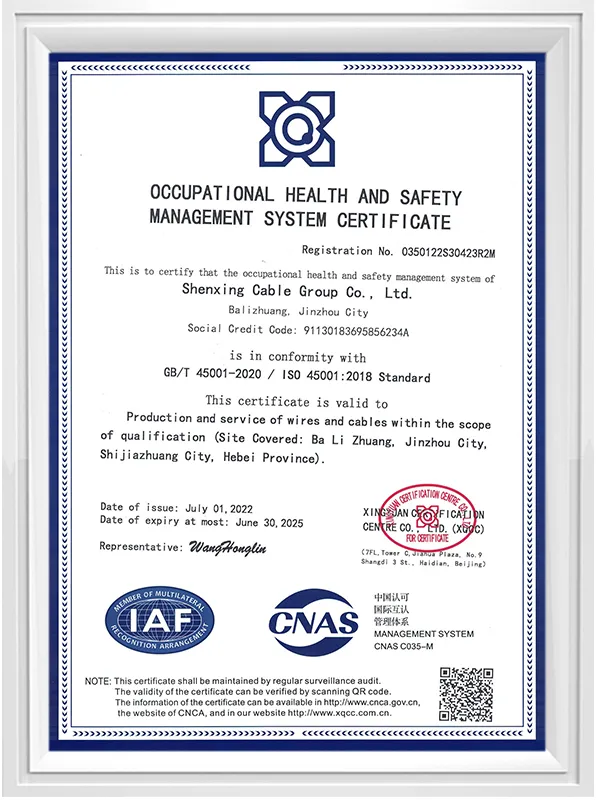

Certificate

TUVRheinland

ISO9001-2015

CE Certificate

ISO14001

ISO45001-2018

ISO50001

Patent

Testing Equipment

Quality Control Process

STEP 01

Excellent performance management model

Actively learn and fully implement the GB/T19580-2004 standard, and successfully build a complete and efficient excellent performance management model.

Successfully passed a series of authoritative and influential certifications in the field of quality, such as ISO9001 quality management system certification, German Rhine product certification and CE certification.

STEP 02

Raw material inspection

1. Analyze the purchased copper, aluminum and other metal raw materials to ensure that their purity and impurity content meet industry standards.

2.Inspect the electrical properties, heat resistance and mechanical properties of insulating materials. For example, use a withstand voltage tester to detect the breakdown voltage of insulating materials, and use an aging box to test their heat resistance and deformation degree.

STEP 03

Production process quality monitoring

1. Perform resistance test on the twisted conductor to ensure that the conductive performance of the conductor meets the requirements. For example, use a bridge to measure the resistance value of the conductor.

2. After insulation extrusion, detect the thickness, eccentricity and appearance quality of the insulation layer. Use a thickness gauge to measure the thickness of the insulation layer, and use optical instruments to check for defects such as bubbles and cracks.

STEP 04

Finished product inspection

1. Conduct electrical performance tests on finished cables, including withstand voltage tests, insulation resistance tests, etc. For example, use a high-voltage test bench, partial discharge tester, apply the specified voltage, and test the cables to ensure that they are 100% qualified

2. Check the mechanical properties of the cables, such as tensile strength, bending performance, etc. Test with a tensile tester and a bending tester.

Perform a comprehensive inspection of the appearance of the cable, including the clarity of the markings, the integrity of the sheath, etc.

STEP 05

Quality data analysis and feedback

Collect and analyze quality inspection data to promptly identify trends and abnormal points of quality fluctuations. Based on the results of data analysis, feedback quality issues to the production department, and propose improvement measures and suggestions.

STEP 06

Personnel training and quality awareness enhancement

Regularly train production personnel and quality inspection personnel to familiarize them with quality standards and testing methods. Strengthen employees' awareness of the importance of quality and encourage employees to actively participate in quality improvement work.

STEP 07

Complete after-sales service system

We have a professional, experienced, and responsible after-sales service team. All members have undergone rigorous training and assessment, have solid professional knowledge and good communication skills, and can quickly and accurately solve customer problems.

Hot Products

Copper Cores, XLPE Insulated, PVC Sheathed, Control Cable

Shenxing KYJV cross-linked power control cable is an advanced integrated intelligent high-voltage cable designed for real-time monitoring of cable operating parameters.

Read More

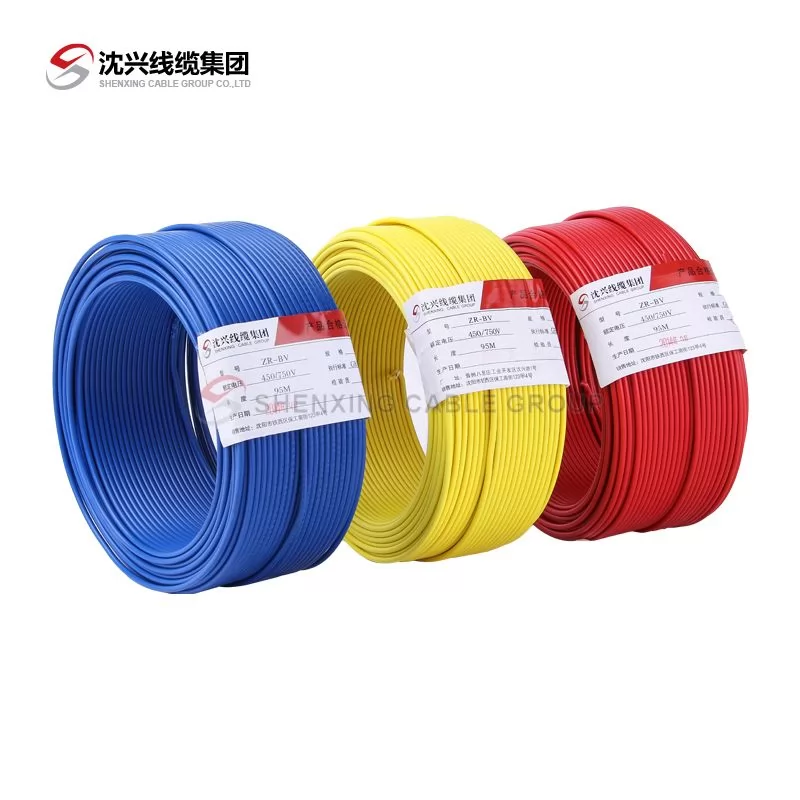

Copper Core PVC Insulated Wire

A global BV cable supplier offers a full variety of building cable from our stock and tailored XLPE cables as well.

Read More

Copper Core PVC Insulated PVC Sheathed Power Cable

BVV/BVVB cable is a high-quality power transmission cable widely used in residential, commercial and industrial environments.

Read More

RVB-Copper Core Flat Sheathless Flexible Cable

Welcome to learn about Shenxing Cable Group's RVV/RVB cable (also known as flexible cable), which is a high-performance cable designed for a variety of low-voltage electrical applications. The cable consists of multiple copper conductors and a PVC outer sheath and is widely used in low-voltage electrical systems.

Read More

Copper Core PVC Insulated Connecting Soft Wire and Cable

Welcome to learn about RV cables from Shenxing Cable Group. This high-quality cable is designed for low-voltage electrical applications. By using high-quality materials and exquisite manufacturing technology, RV cables ensure that you enjoy reliable power supply and efficient power transmission in multiple fields, providing you with ideal solutions.

Read More

RVV cable is suitable for a variety of application scenarios, including home power wiring, industrial equipment connections, office electrical systems, etc. Whether it is used for power transmission, electrical equipment connection, or use in harsh environments, RVV cables can provide stable, efficient, and safe power support.

Read More

Copper Conductor, PVC Insulated and Sheathed, Steel-tape Armoured Control Cable

RVS twisted pair flexible cable provided by Shenxing Cable Group is a 300/500V voltage level cable consisting of two insulated conductors twisted around each other. We produce many types of twisted pair cables in strict accordance with the Chinese national standard GB/T 8734.3. RVS twisted pair shielded cable consists of two independent insulated copper conductors that are twisted around each other and arranged in parallel.

Read More

TÜV Solar PV Cable TÜV-H1Z2Z2-K

The SHENXING solar PV H1Z2Z2-K cable, which is TÜV certified according to EN 50618 and AENOR, is suitable for both fixed and mobile solar installations (solar farms, rooftop solar installations and floating plants). It is a highly flexible cable compatible with all major connectors and specially designed for the connection of photovoltaic panels. This versatile single-conductor cable is designed to meet the varying needs of the solar industry. Suitable for wet, damp and humid locations.

Read More

Shenxing Photovoltaic Cable PV1-F is a high-performance cable designed for solar photovoltaic systems. It has excellent high temperature resistance, extrusion resistance, environmental cracking resistance and other characteristics, ensuring the long-term stable operation of photovoltaic power generation systems. As a leading global photovoltaic cable manufacturer and supplier, Shenxing Cable is committed to providing high-quality cable solutions to meet the needs of various photovoltaic installa

Read More

110kv Copper Core XLPE Insulated Corrugated Aluminum Sheathed Power Cable

YJLW high voltage cross-linked polyethylene cable is a high-quality cable product for high voltage power transmission. It adopts high-quality copper core, aluminum core and cross-linked polyethylene insulation materials to ensure the high efficiency and reliability of power transmission.

Read More

Request Your Free Electrical Cable Quote Today